The Story of the Bent Valves - March 2022

On Saturday 26 March 2022, I competed in the Cadwell Park sprint on a surprisingly sunny and warm day. This was my first visit to Cadwell Park since a

trackday in April 2007. Practice went well, but on my first timed run, as I exited Charlies I felt a knock under my seat. On checking the gauges,

everything looked fine and the car was still pulling nicely along Park Straight. As I left the circuit at The Mountain and headed back to the paddock,

I noticed coolant streaking along the bonnet. On returning to my paddock space I removed the bonnet to find coolant everywhere and noticed the catch tank

was overflowing with coolant. The next thing I noticed was the alternator belt had come off and was still in one piece followed by the surprise that the

alternator fan had gone AWOL. I suspect it was this that hit the underside of the car. As the alternator belt drives the water pump this would explain the

overheating issue. In fact, once the engine had cooled, most of the coolant in the catch tank was sucked back into the engine. Game over. I cleared up the

mess in the engine bay, loaded the car onto the trailer and headed home.

The following day, I was having another look in the engine bay and to my horror noticed that the cambelt was badly damaged and this would

have been the result of the alternator fan flying off into the cambelt. As you can see from the photos below, the cambelt was in a very poor state and it is

probably a minor miracle that it did not let go and destroy the engine completely, considering my speed at the time. The escaping fan also took chunks out of

the idler, tensioner and water pump pulleys.

On the Zetec, the alternator is on the right hand side and the fan is quite close to the front brake union, so when I installed the Zetec

I decided to bolt a flat metal plate over the brake union for some protection. The plate, as you can see from the photo below, did its job. The brake union

and pipes remained intact.

As it was Sunday, there was not a lot I could do, but I decided to prepare the car for a new cambelt and pulleys. Monday came and my local

motor factor ordered the parts and I was able to collect the same day. On Tuesday I had time to fix the car, as on Thursday we were travelling to Anglesey

for a weekend of sprinting.

Methodically I worked through everything and by the afternoon I stepped back and admired my handy work and looked forward to a beer! But then

I suddenly realised that the idler pulley was not straight and something was not right. It dawned on me that I had cross-threaded the bolt that goes into the

block. I took the cambelt off and removed the idler pulley and tried again, but there was no resistance on tightening the bolt. It was now apparent that I had

stripped the thread in the head!!

A local 7 owner/mechanic advised that I needed to use a Time Sert to repair the thread and by chance he was able to lend me one. I have never

used one before, but I followed the instructions and re-installed the idler pulley etc and all was good. The engine ran fine and I intended to take the 7

for a run the next day.

The next day dawned and I started her up and checked everything again and finally headed off along our road, which is downhill. A few minutes

later, I was heading uphill and I started to hear a few 'clinking' noises and decided to pull over and just as I did so the engine died. I removed the bonnet

to be greeted by an idler pulley dangling from the block.

Ever the optimist, I hoped that as I was doing no more that 20-25mph when this happened, I might be lucky. Sadly this was not the case.

I am so glad I took the 7 for a quick run, as I hate to think of the damage that would have ensued when setting off at full pelt from the start line at

Anglesey! Fortunately, I was offered a dual drive by Mike Sankey, so I just shut the garage door and decided to deal with it all on my return.

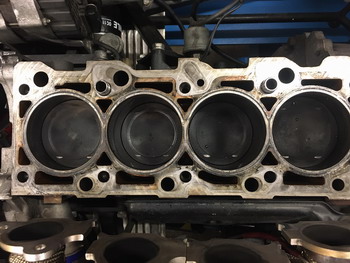

The following week I removed the head and the damage was all too apparent. I could clearly see the witness marks on the pistons and the bent

valves in the head.

Fortunately, the crowns on the pistons had only lightly been marked and once they had been cleaned up I was able to deburr the edges of

the valve marks.

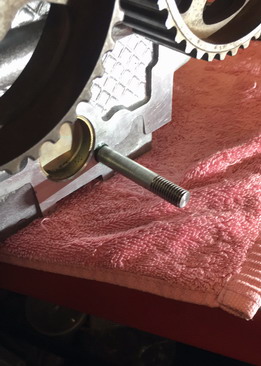

I was recommended to take the head to Dave at Boss Racing and the main concern was that the thread for the idler pulley bolt was very close

to the water jacket and core plug in the head. Dave suggested making a threaded stud to permanently fix into the head and then machining a slim boss so that

the pulley could be secured with a flange nut.

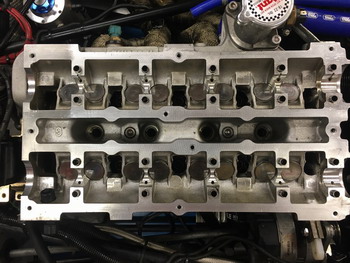

Dave reassembled the head with new valves from Raceline and new oil stem seals. Fortunately, the valve guides were undamaged and finally I

was able to reassemble everything...

This time, as expected, everything ran smoothly and the 7 was ready for the Curborough Sprint in May. Naturally, on the first run I was a

little anxious, but she ran like a dream.

I did request return of the old valves for posterity. In all, 12 were bent in varying degrees and I could not resist mounting them as another

'unwanted trophy' to go with 'Piston Broke' from 2010.

Looking back, I have tried to understand how I managed to cross-thread the idler pulley bolt and why the Time Sert failed. I think the main

reason is desperately wanting to get the car ready for that next sprint and not taking as much time/care as I thought I was taking. Lesson learnt!